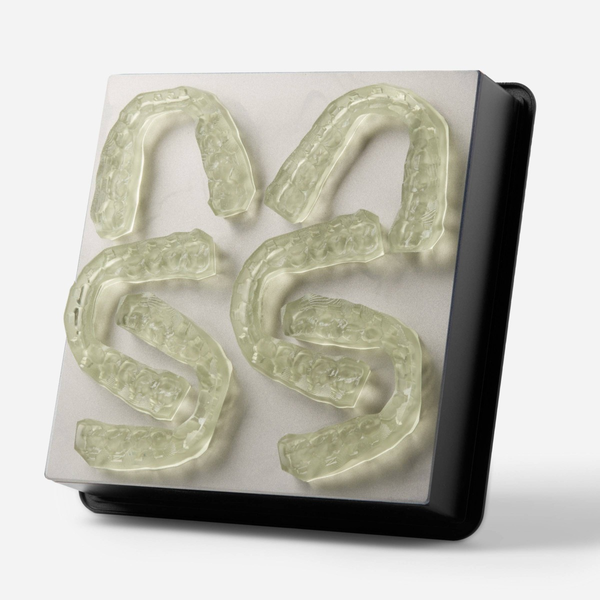

IBT Resin (Form 3) 1 L

RS-F2-IBCL-01

IBT Resin is our first generation biocompatible material for indirect bonding trays. Choose IBT Flex Resin instead for our latest material formulation with enhanced flexibility, strength, translucency, and color.

Read our Application Guide to learn the complete digital workflow and best practices for making 3D printed indirect bonding trays on your Formlabs 3D printer.

Note: IBT Resin (V1) will no longer be available for direct purchase beginning on Friday, June 7, 2024. Formlabs recommends switching to IBT Flex Resin. IBT Flex Resin is a Class I biocompatible material with enhanced flexibility, strength, translucency, and color to guarantee optimal clinical outcomes while providing a great patient experience and for seamless and precise transfer of orthodontic brackets and restorative composite materials. 3D print flexible and tear-resistant translucent trays and guides that save you time and deliver consistent, predictable outcomes.

- IBT Resin (Form 3) 1 L

Why Choose IBT Resin?

IBT Resin is a flexible material that enables efficient, accurate orthodontic bracket placement.

High Throughput

Print full arch and quadrant bracket transfer trays using 100 micron layer heights, reducing labor time and enabling higher throughput.

Ease of Use and Comfort

Produce soft and flexible appliances that are easy to work with and comfortable for the patient.

Proven Efficiency and Quality

Streamline workflows with optimized tear strength, translucency, and flexibility.

Biocompatibility

Provide the patient and clinician the peace of mind they deserve.

Applications

IBT Resin can be used to 3D print indirect bonding trays for a cost-effective, rapid dental bracket placement process for high-quality orthodontics.

Consider IBT Resin for:

Material Properties*

IBT Resin

Ultimate Tensile Strength

Young's Modulus

Elongation

Hardness Shore A

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Data were measured on post-cured samples printed on a Form 3B with 100um IBT Resin settings, washed in a Form Wash for 20 minutes in ≥99% Isopropyl Alcohol.